Custom jeteduplex Nerjaveèi asye envestisman Distribisyon pwodwisoti nan Lachin Distribisyon fondri ak machining, tretman chalè, ak sèvis tretman sifas yo.

RMC jetepresizyon jete pati asyeki toujou satisfè oswa depase atant kliyan yo. Distribisyon envestisman sir pèdi pèmèt nou pwodwi pati metal piti tankou dè dizèn de gram ak gwo tankou dè dizèn de kilogram, nan yon pakèt alyaj fèr ak ki pa FERROUS ak ak presizyon dimansyon eksepsyonèl.

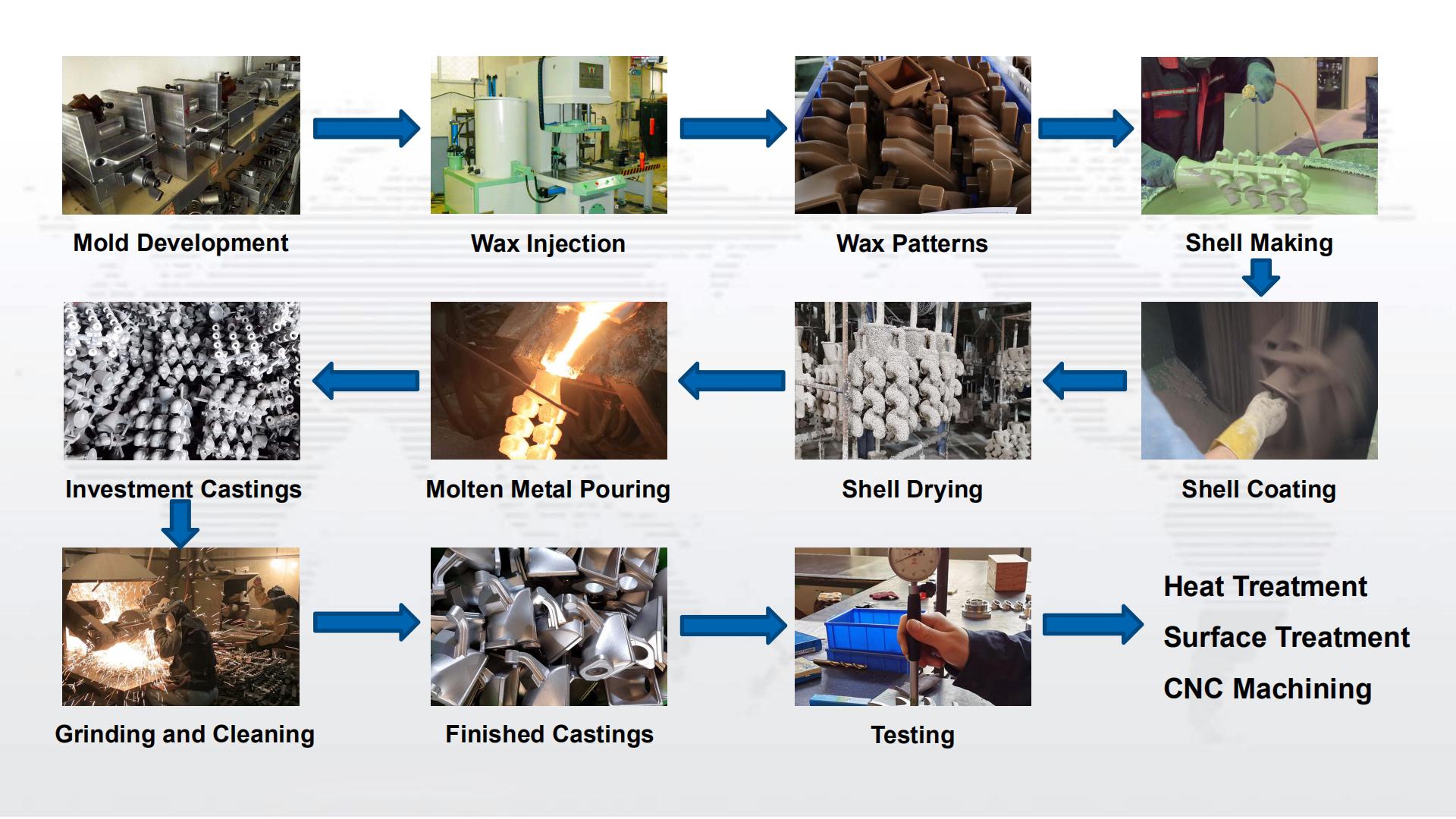

Pwosesis depoze sir ki pèdi a pwodui pati metal presizyon tou pre-fòm ki souvan mande pou ti kras oswa pa gen okenn machin adisyonèl. Fini a ki kapab lakòz se tou pi bon pase sa ki ka reyalize atravè lòt pwosesis. Fòs la ak rezistans nan pati yo Distribisyon fè tèt yo ideyal pou aplikasyon pou segondè-rezistans ki mande dè milyon de sik.

Duplex Nerjaveèi (DSS) refere a asye pur ak ferit ak austenite chak kontablite pou apeprè 50%. Anjeneral, kontni an nan mwens faz bezwen omwen 30%. Nan ka a nan kontni C ki ba, kontni an Cr se 18% a 28%, ak kontni an Ni se 3% a 10%. Gen kèk asye pur duplex gen ladan tou eleman alyaj tankou Mo, Cu, Nb, Ti, ak N.

Klas ki disponib nan asye pur duplex nan RMC Casting Foundry: 1.4460, 1.4462, 1.4468, 1.4469, 1.4517, 1.4770, A 890 1C, A 890 1A, A 890 3A, A 890 3A, A 890 4A, A 898 4A, A 898 1B, A 995 4A, A 995 5A, 2205, 2507, 022Cr22Ni5Mo3N, 022Cr25Ni6Mo2N

DSS la gen karakteristik asye pur austenitic ak feritik. Konpare ak ferit, li gen pi wo plastisit ak duktilite, pa gen okenn brittleness tanperati chanm, ak siyifikativman amelyore rezistans korozyon intergranular ak pèfòmans soude, pandan y ap toujou kenbe frajil, segondè konduktiviti tèmik, ak superplasticity kòm ferit asye pur. Konpare ak asye pur austenitic, DSS gen gwo fòs ak siyifikativman amelyore rezistans nan korozyon intergranular ak korozyon estrès klori. Duplex Nerjaveèi gen ekselan rezistans korozyon pitting epi li se tou yon asye pur nikèl-ekonomize.

| Klas ekivalan nan asye pur | |||||||

| Gwoup | AISI | W-stoff | DIN | BS | SS | UNE / IHA | UNI |

| Martensitic ak Ferritic Nerjaveèi | 420 C | 1,4034 | X43Cr16 | ||||

| 440 B/1 | 1,4112 | X90 Cr Mo V18 | |||||

| - | 1.2083 | X42 Cr 13 | - | 2314 | F.5263 | - | |

| 403 | 1.4000 | X6Cr13 | 403 S 17 | 2301 | F.3110 | X6Cr13 | |

| (410S) | 1.4001 | X7 Cr 14 | (403 S17) | 2301 | F.3110 | X6Cr13 | |

| 405 | 1.4002 | X6 CrAl 13 | 405 S 17 | - | F.3111 | X6 CrAl 13 | |

| 416 | 1.4005 | X12 CrS 13 | 416 S 21 | 2380 | F.3411 | X12CrS13 | |

| 410 | 1.4006 | X 10 Cr 13 | 410 S21 | 2302 | F.3401 | X12Cr13 | |

| 430 | 1.4016 | X6 Cr 17 | 430 S 17 | 2320 | F.3113 | X8Cr17 | |

| 420 | 1.4021 | X20 Cr 13 | 420 S 37 | 2303 | F.3402 | X20Cr13 | |

| 420F | 1.4028 | X30 Cr 13 | 420 S 45 | (2304) | F.3403 | X30Cr13 | |

| (420) | 1.4031 | X39Cr13 | 420 S 45 | (2304) | F.3404 | - | |

| 431 | 1.4057 | X20 CrNi 17 2 | 431 S 29 | 2321 | F.3427 | X16CrNi16 | |

| 430F | 1.4104 | X12 CrMoS 17 | - | 2383 | F.3117 | X10CrS17 | |

| 434 | 1.4113 | X6 CrMo 17 | 434 S 17 | 2325 | - | X8CrMo17 | |

| 430Ti | 1.4510 | X6 CrTi 17 | - | - | - | X6CrTi17 | |

| 409 | 1.4512 | X5 CrTi 12 | 409 S 17 | - | - | X6CrTi12 | |

| Austenitic Nerjaveèi | 304 | 1.4301 | X5 CrNi 18 9 | 304 S 15 | 2332 | F.3551 | X5CrNi18 10 |

| 305 | 1.4303 | X5 CrNi 18 12 | 305 S 19 | - | - | X8CrNi19 10 | |

| 303 | 1.4305 | X12 CrNiS 18 8 | 303 S 21 | 2346 | F.3508 | X10CrNiS 18 09 | |

| 304L | 1.4306 | X2 CrNiS 18 9 | 304 S 12 | 2352 | F.3503 | X2CrNi18 11 | |

| 301 | 1.4310 | X12 CrNi 17 7 | - | 2331 | F.3517 | X12CrNi17 07 | |

| 304 | 1.4350 | X5 CrNi 18 9 | 304 S 31 | 2332 | F.3551 | X5CrNi18 10 | |

| 304 | 1.4350 | X5 CrNi 18 9 | 304 S 31 | 2333 | F.3551 | X5CrNi18 10 | |

| 304LN | 1.4311 | X2 CrNiN 18 10 | 304 S 62 | 2371 | - | - | |

| 316 | 1.4401 | X5 CrNiMo 18 10 | 316 S 16 | 2347 | F.3543 | X5CrNiMo17 12 | |

| 316L | 1.4404 | - | 316 S 12/13/14/22/24 | 2348 | X2CrNiMo17 12 | ||

| 316LN | 1.4429 | X2 CrNiMoN 18 13 | - | 2375 | - | - | |

| 316L | 1.4435 | X2 CrNiMo 18 12 | 316 S 12/13/14/22/24 | 2353 | - | X2CrNiMo17 12 | |

| 316 | 1.4436 | - | 316 S 33 | 2343 | - | X8CrNiMo 17 13 | |

| 317L | 1.4438 | X2 CrNiMo 18 16 | 317 S 12 | 2367 | - | X2CrNiMo18 16 | |

| 329 | 1.4460 | X3 CrNiMoN 27 5 2 | - | 2324 | F.3309 | - | |

| 321 | 1.4541 | X10 CrNiTi 18 9 | 321 S 12 | 2337 | F.3553 | X6CrNiTi18 11 | |

| 347 | 1.4550 | X10 CrNiNb 18 9 | 347 S 17 | 2338 | F.3552 | X6CrNiNb18 11 | |

| 316Ti | 1.4571 | X10 CrNiMoTi 18 10 | 320 S 17 | 2350 | F.3535 | X6CrNiMoTi 17 12 | |

| 309 | 1.4828 | X15 CrNiSi 20 12 | 309 S 24 | - | - | X16 CrNi 24 14 | |

| 330 | 1.4864 | X12 NiCrSi 36 16 | - | - | - | - | |

| Duplex Nerjaveèi | S32750 | 1.4410 | X 2 CrNiMoN 25 7 4 | - | 2328 | - | - |

| S31500 | 1.4417 | X 2 CrNiMoSi 19 5 | - | 2376 | - | - | |

| S31803 | 1.4462 | X 2 CrNiMoN 22 5 3 | - | 2377 | - | - | |

| S32760 | 1.4501 | X 3 CrNiMoN 25 7 | - | - | - | - | |

| 630 | 1.4542 | X5CrNiCNb16-4 | - | - | - | - | |

| A564/630 | - | - | - | - | - | - | |

▶ Metal fèr ak metal ki pa fèr pouDistribisyon envestisman, Pwosesis Distribisyon Sir Objè:

• Gri Iron: HT150, HT200, HT250, HT300, HT350; GJL-100, GJL-150, GJL-200, GJL-250, GJL-300, GJL-350; GG10 ~ GG40.

• Ductile Iron oswa Nodular Iron: GGG40, GGG50, GGG60, GGG70, GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2; QT400-18, QT450-10, QT500-7, QT600-3, QT700-2, QT800-2;

• Carbon Steel: AISI 1020 - AISI 1060, C30, C40, C45.

• Steel Alliages: ZG20SiMn, ZG30SiMn, ZG30CrMo, ZG35CrMo, ZG35SiMn, ZG35CrMnSi, ZG40Mn, ZG40Cr, ZG42Cr, ZG42CrMo... elatriye sou demann.

• Nerjaveèi: AISI 304, AISI 304L, AISI 316, AISI 316L, 1.4401, 1.4301, 1.4305, 1.4307, 1.4404, 1.4571 ak lòt klas asye pur.

• Kwiv, Wouj Copper, Bwonz oswa lòt metal alyaj ki baze sou Copper: ZCuZn39Pb3, ZCuZn39Pb2, ZCuZn38Mn2Pb2, ZCuZn40Pb2, ZCuZn16Si4

• Lòt Materyèl dapre kondisyon inik ou oswa dapre estanda ASTM, SAE, AISI, ACI, DIN, EN, ISO, ak GB

▶ Kapasite nanFondasyon Distribisyon Envestisman

• Max Size: 1,000 mm × 800 mm × 500 mm

• Ranje pwa: 0.5 kg - 100 kg

• Kapasite anyèl: 2,000 tòn

• Materyèl Kolèj pou Konstriksyon Shell: Sol Silica, vè dlo ak melanj yo.

| Sèvis | Deskripsyon |

| Sèvis Tretman Sifas | Kouch poud, Anodizasyon, Electrophotesis, Chrome Plating, Penti, sab eksplozif, Nickel Plating, Zenk Plating, Blacking, Polissage, Bluing, Geormet, Zintek, elatriye. |

| CNC Precision Machining Sèvis | Lathing, Fraisage, Vire, Honing, Perçage, raz, Tapping, Fil Elektwòd Koupe, Manje ... elatriye. |

| Enspeksyon ak Kontwòl Kalite | Spectrum Analyzer, CMM, Tester dite, tèsteur fòs rupture, tèsteur Yild Strentgh, tèsteur presyon sele, analizeur souf kabòn, mikwoskospi metaliji, tès fòs pou laprès ... elatriye. |