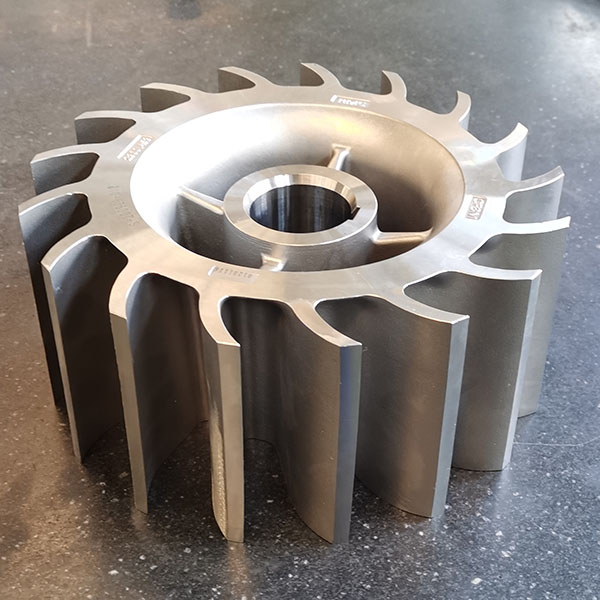

OEM koutim duplex 2205/1.4462 depoze asye pur ak sèvis CNC D 'ki soti nan Lachinfonderie depoze envestisman.

Duplex 2205 Distribisyon asye purvle di depoze yo te fè nan duplex asye pur. Duplex Nerjaveèi (DSS) refere a asye pur ak ferit ak austenite chak kontablite pou apeprè 50%. Anjeneral, kontni an nan mwens faz bezwen omwen 30%. Nan ka a nan kontni C ki ba, kontni an Cr se 18% a 28%, ak kontni an Ni se 3% a 10%. Gen kèk asye pur duplex gen ladan tou eleman alyaj tankou Mo, Cu, Nb, Ti, ak N.

DSS la gen karakteristik asye pur austenitic ak feritik. Konpare ak ferit, li gen pi wo plastisit ak duktilite, pa gen okenn frajil tanperati chanm, ak siyifikativman amelyore rezistans korozyon intergranular ak pèfòmans soude, pandan y ap toujou kenbe frajil, segondè konduktiviti tèmik, ak plastisit super kòm ferit asye pur. Konpare ak asye pur austenitic, DSS gen gwo fòs ak siyifikativman amelyore rezistans nan korozyon intergranular ak korozyon estrès klori.Duplex Nerjaveèigen ekselan rezistans korozyon pitting epi li se tou yon nikèl-ekonomize asye pur.

| Materyèl pouPwosesis Distribisyon Envestismannan RMC

| |||

| Kategori | Lachin Klas | US Klas | Almay Klas |

| Ferritik Nerjaveèi | 1Cr17, 022Cr12, 10Cr17, | 430, 431, 446, CA-15, CA6N, CA6NM | 1.4000, 1.4005, 1.4008, 1.4016, GX22CrNi17, GX4CrNi13-4 |

| Martensitic Nerjaveèi | 1Cr13, 2Cr13, 3Cr13, 4Cr13, | 410, 420, 430, 440B, 440C | 1.4021, 1.4027, 1.4028, 1.4057, 1.4059, 1.4104, 1.4112, 1.4116, 1.4120, 1.4122, 1.4125 |

| Austenitic Nerjaveèi | 06Cr19Ni10, 022Cr19Ni10, 06Cr25Ni20, 022Cr17Ni12Mo2, 03Cr18Ni16Mo5 | 302, 303, 304, 304L, 316, 316L, 329, CF3, CF3M, CF8, CF8M, CN7M, CN3MN | 1.3960, 1.4301, 1.4305, 1.4306, 1.4308, 1.4313, 1.4321, 1.4401, 1.4403, 1.4404, 1.4405, 1.4406, 9, 1.4406, 9, 1.4406 1.4435, 1.4436, 1.4539, 1.4550, 1.4552, 1.4581, 1.4582, 1.4584, |

| Presipitasyon redi Nerjaveèi | 05Cr15Ni5Cu4Nb, 05Cr17Ni4Cu4Nb | 630, 634, 17-4PH, 15-5PH, CB7Cu-1 | 1.4542 |

| Duplex Nerjaveèi | 022Cr22Ni5Mo3N, 022Cr25Ni6Mo2N | A 890 1C, A 890 1A, A 890 3A, A 890 4A, A 890 5A, A 995 1B, A 995 4A, A 995 5A, 2205, 2507 | 1.4460, 1.4462, 1.4468, 1.4469, 1.4517, 1.4770 |

| High Mn Steel | ZGMn13-1, ZGMn13-3, ZGMn13-5 | B2, B3, B4 | 1.3802, 1.3966, 1.3301, 1.3302 |

| Zouti Steel | Cr12 | A5, H12, S5 | 1.2344, 1.3343, 1.4528, GXCrMo17, X210Cr13, GX162CrMoV12 |

| Steel ki reziste chalè | 20Cr25Ni20, 16Cr23Ni13, 45Cr14Ni14W2Mo | 309, 310, CK20, CH20, HK30 | 1.4826, 1.4828, 1.4855, 1.4865 |

| Nickle-baz alyaj | HASTELLY-C, HASTELLY-X, SUPPER22H, CW-2M, CW-6M, CW-12MW, CX-2MW, HX(66Ni-17Cr), MRE-2, NA-22H, NW-22, M30C, M-35 -1, INCOLOY600, INCOLOY625 | 2.4815, 2.4879, 2.4680 | |

| Aliminyòm Alyaj | ZL101, ZL102, ZL104 | ASTM A356, ASTM A413, ASTM A360 | G-AlSi7Mg, G-Al12 |

| Alloy kòb kwiv mete | H96, H85, H65, HPb63-3, HPb59-1, QSn6.5-0.1, QSn7-0.2 | C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 | CuZn5, CuZn15, CuZn35, CuZn36Pb3, CuZn40Pb2, CuSn10P1, CuSn5ZnPb, CuSn5Zn5Pb5 |

| Cobalt-baz alyaj | UMC50, 670, Klas 31 | 2.4778 | |