Nerjaveèi gen yon kontni chromium minimòm de 10.5%, ki fè li pi rezistan nan anviwònman likid korozif ak oksidasyon. Li trè rezistan korozyon ak mete rezistan, bay machinabilite ekselan, epi li se byen li te ye pou aparans ayestetik li yo. Distribisyon envestisman asye pur yo se "korozyon ki reziste" lè yo itilize nan anviwònman likid ak vapè anba a 1200 ° F (650 ° C) ak "chalè ki reziste" lè yo itilize pi wo a tanperati sa a.

Klas ekivalan nan asye pur | |||||||

| Kategori | AISI | W-stoff | DIN | BS | SS | UNE / IHA | UNI |

| Martensitic ak Ferritic Nerjaveèi | 420 C | 1.4034 | X43Cr16 | ||||

| 440 B/1 | 1.4112 | X90 Cr Mo V18 | |||||

| - | 1.2083 | X42 Cr 13 | - | 2314 | F.5263 | - | |

| 403 | 1.4000 | X6Cr13 | 403 S 17 | 2301 | F.3110 | X6Cr13 | |

| (410S) | 1.4001 | X7 Cr 14 | (403 S17) | 2301 | F.3110 | X6Cr13 | |

| 405 | 1.4002 | X6 CrAl 13 | 405 S 17 | - | F.3111 | X6 CrAl 13 | |

| 416 | 1.4005 | X12 CrS 13 | 416 S 21 | 2380 | F.3411 | X12CrS13 | |

| 410 | 1.4006 | X 10 Cr 13 | 410 S21 | 2302 | F.3401 | X12Cr13 | |

| 430 | 1.4016 | X6 Cr 17 | 430 S 17 | 2320 | F.3113 | X8Cr17 | |

| 420 | 1.4021 | X20 Cr 13 | 420 S 37 | 2303 | F.3402 | X20Cr13 | |

| 420F | 1.4028 | X30 Cr 13 | 420 S 45 | (2304) | F.3403 | X30Cr13 | |

| (420) | 1.4031 | X39Cr13 | 420 S 45 | (2304) | F.3404 | - | |

| 431 | 1.4057 | X20 CrNi 17 2 | 431 S 29 | 2321 | F.3427 | X16CrNi16 | |

| 430F | 1.4104 | X12 CrMoS 17 | - | 2383 | F.3117 | X10CrS17 | |

| 434 | 1.4113 | X6 CrMo 17 | 434 S 17 | 2325 | - | X8CrMo17 | |

| 430Ti | 1.4510 | X6 CrTi 17 | - | - | - | X6CrTi17 | |

| 409 | 1.4512 | X5 CrTi 12 | 409 S 17 | - | - | X6CrTi12 | |

| Austenitic Nerjaveèi | 304 | 1.4301 | X5 CrNi 18 9 | 304 S 15 | 2332 | F.3551 | X5CrNi18 10 |

| 305 | 1.4303 | X5 CrNi 18 12 | 305 S 19 | - | - | X8CrNi19 10 | |

| 303 | 1.4305 | X12 CrNiS 18 8 | 303 S 21 | 2346 | F.3508 | X10CrNiS 18 09 | |

| 304L | 1.4306 | X2 CrNiS 18 9 | 304 S 12 | 2352 | F.3503 | X2CrNi18 11 | |

| 301 | 1.4310 | X12 CrNi 17 7 | - | 2331 | F.3517 | X12CrNi17 07 | |

| 304 | 1.4350 | X5 CrNi 18 9 | 304 S 31 | 2332 | F.3551 | X5CrNi18 10 | |

| 304 | 1.4350 | X5 CrNi 18 9 | 304 S 31 | 2333 | F.3551 | X5CrNi18 10 | |

| 304LN | 1.4311 | X2 CrNiN 18 10 | 304 S 62 | 2371 | - | - | |

| 316 | 1.4401 | X5 CrNiMo 18 10 | 316 S 16 | 2347 | F.3543 | X5CrNiMo17 12 | |

| 316L | 1.4404 | - | 316 S 12/13/14/22/24 | 2348 | X2CrNiMo17 12 | ||

| 316LN | 1.4429 | X2 CrNiMoN 18 13 | - | 2375 | - | - | |

| 316L | 1.4435 | X2 CrNiMo 18 12 | 316 S 12/13/14/22/24 | 2353 | - | X2CrNiMo17 12 | |

| 316 | 1.4436 | - | 316 S 33 | 2343 | - | X8CrNiMo 17 13 | |

| 317L | 1.4438 | X2 CrNiMo 18 16 | 317 S 12 | 2367 | - | X2CrNiMo18 16 | |

| 329 | 1.4460 | X3 CrNiMoN 27 5 2 | - | 2324 | F.3309 | - | |

| 321 | 1.4541 | X10 CrNiTi 18 9 | 321 S 12 | 2337 | F.3553 | X6CrNiTi18 11 | |

| 347 | 1.4550 | X10 CrNiNb 18 9 | 347 S 17 | 2338 | F.3552 | X6CrNiNb18 11 | |

| 316Ti | 1.4571 | X10 CrNiMoTi 18 10 | 320 S 17 | 2350 | F.3535 | X6CrNiMoTi 17 12 | |

| 309 | 1.4828 | X15 CrNiSi 20 12 | 309 S 24 | - | - | X16 CrNi 24 14 | |

| 330 | 1.4864 | X12 NiCrSi 36 16 | - | - | - | - | |

| Duplex Nerjaveèi | S32750 | 1.4410 | X 2 CrNiMoN 25 7 4 | - | 2328 | - | - |

| S31500 | 1.4417 | X 2 CrNiMoSi 19 5 | - | 2376 | - | - | |

| S31803 | 1.4462 | X 2 CrNiMoN 22 5 3 | - | 2377 | - | - | |

| S32760 | 1.4501 | X 3 CrNiMoN 25 7 | - | - | - | - | |

| 630 | 1.4542 | X5CrNiCNb16-4 | - | - | - | - | |

| A564/630 | - | - | - | - | - | - | |

Materyèl FERROUS ak ki pa FERROUS pou Distribisyon Envestisman, Pwosesis Distribisyon sir pèdi:

- • Gri Iron: HT150, HT200, HT250, HT300, HT350; GJL-100, GJL-150, GJL-200, GJL-250, GJL-300, GJL-350; GG10 ~ GG40.

- • Ductile Iron oswa Nodular Iron: GGG40, GGG50, GGG60, GGG70, GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2; QT400-18, QT450-10, QT500-7, QT600-3, QT700-2, QT800-2;

- • Carbon Steel: AISI 1020 - AISI 1060, C30, C40, C45.

- • Steel Alliages: ZG20SiMn, ZG30SiMn, ZG30CrMo, ZG35CrMo, ZG35SiMn, ZG35CrMnSi, ZG40Mn, ZG40Cr, ZG42Cr, ZG42CrMo... elatriye sou demann.

- • Nerjaveèi: AISI 304, AISI 304L, AISI 316, AISI 316L, 1.4401, 1.4301, 1.4305, 1.4307, 1.4404, 1.4571 ak lòt klas asye pur.

- • Kwiv, Wouj Copper, Bwonz oswa lòt metal alyaj ki baze sou Copper: ZCuZn39Pb3, ZCuZn39Pb2, ZCuZn38Mn2Pb2, ZCuZn40Pb2, ZCuZn16Si4

- • Lòt Materyèl dapre kondisyon inik ou oswa dapre estanda ASTM, SAE, AISI, ACI, DIN, EN, ISO, ak GB

Aplikasyon nan Distribisyon Custom nou yo ak Pati Machining:

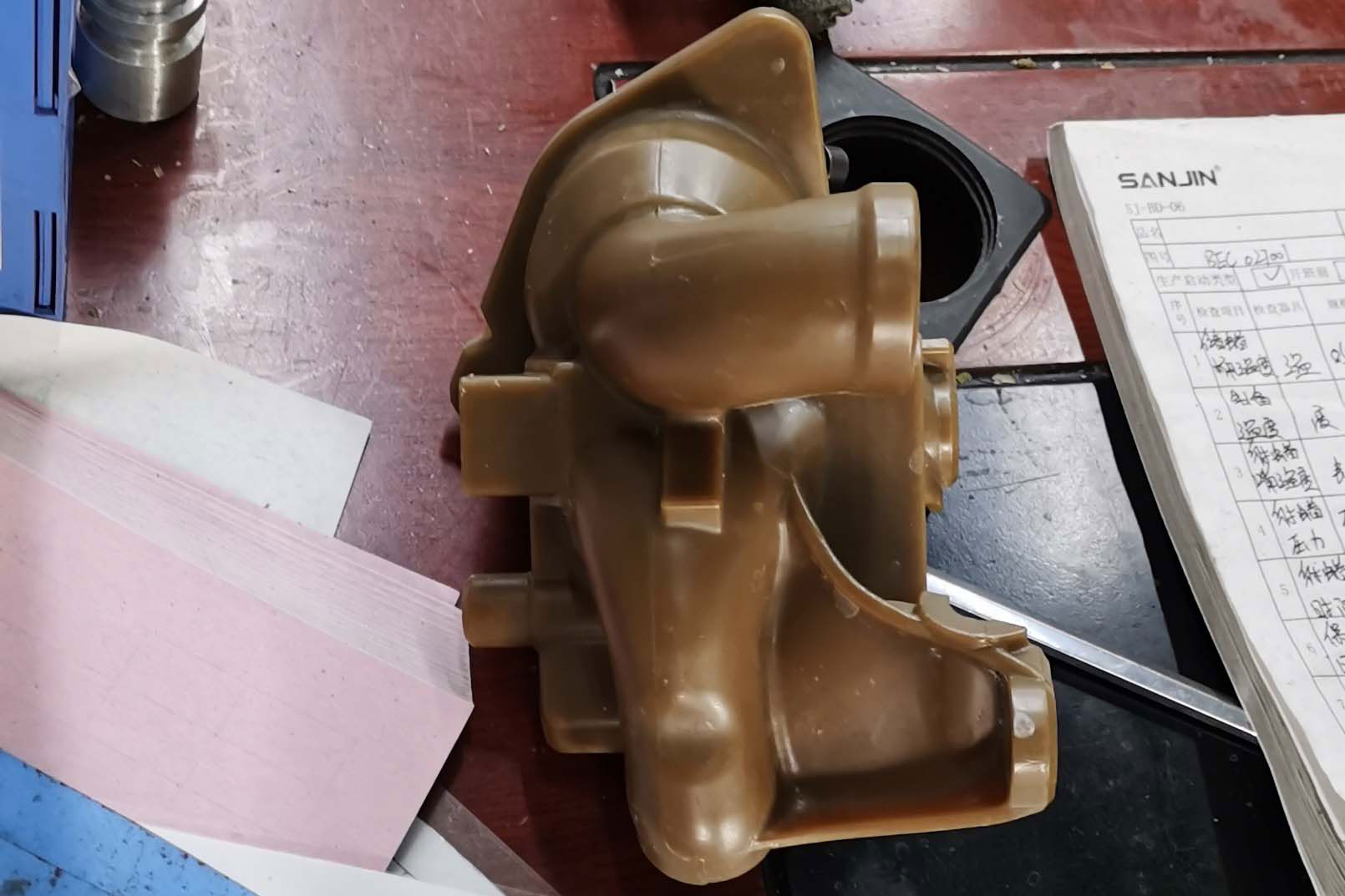

- 1. Pati oto: disk fren, konekte baton, aks kondwi, arbr kondwi, bra kontwòl, lojman bwat, kouvèti bwat, kouvèti anbreyaj, lojman anbreyaj, wou, Lojman filtre, CV Joint Lojman, Lock Hook.

- 2. Pati Kamyon: Rocker Arms, Transmisyon Transmisyon, Aks Kondwi, Kovèti pou Lojman, Kovèti pou Kovèti pou, Je Remorquage, Konekte Rod, Blòk Motè, Kouvèti Motè, Boulon Joint, Dekolaj pouvwa, Arbr, Camshaft, Pan lwil oliv.

- 3. idwolik pati: idwolik yo opere silenn, idwolik yo opere ponp, Gerotor Lojman, Vane, coussinets, idwolik yo opere tank, idwolik yo opere silenn tèt, idwolik yo opere silenn triyang Support.

- 4. Machin Agrikòl ak Pati Traktè: Kovèti pou Lojman, Kovèti pou Kovèti pou, Konekte Rod, Torque Rod, Blòk motè, Kouvèti motè, Lojman ponp lwil oliv, Support, Hanger, Hook, Support.

- 5. tren tren ak machin machandiz yo: chòk absòbe Lojman, chòk absòbe kouvèti, Draft Kovèti pou Lojman, Draft Kovèti pou kouvri, Wedge ak kòn, wou, sistèm fren, manch, Guids.

- 6. Pati machin konstriksyon: Kovèti pou, Syèj kote yo pote, Ponp Kovèti pou, Lojman bwat, kouvèti bwat, bride, kous, silenn boom, sipò sipò, tank idwolik, dan bokit, bokit.

- 7. Pati Ekipman Lojistik: Wou, Caster, Support, Silenn idwolik, pyès rezèv chariot, Ka fèmen.

- 8. Valv ak Pati Ponp: Valv Kò (Lojman), Papiyon Valv Disk, Boul Valv Lojman, Flange, Connector, Camlock, Open Impeller, Fèmen Impeller, Lojman Ponp (Kò), Kouvèti Ponp.

Tretman chalè nan Distribisyon asye pur AISI 316:

Chalè a 1900 ° F (1040 ° C) minimòm, kenbe pou ase tan, etenn nan dlo oswa fre rapid pa lòt mwayen. AISI 316 egal a CF8M/F316 ak Chinwa Creole 0Cr17Ni12Mo2. AISI 314 se yon modifikasyon portant molybdène nan alyaj AISI 304 epi li se ekivalan jete nan asye CF8M Nerjaveèi fòje. Prezans nan molybdène ogmante rezistans jeneral korozyon ak rezistans nan pitting pa klori. Se alyaj la itilize nan kondisyon ki twò asid ak alkalin ak pou manyen asid asid, oksalik ak fosfò.